Room Ventilation

Ventilating a blast room can be done by three different methods of air-flow design. The three air-flow designs are “down-draft”, “end-to-center” and “cross-draft” ventilation.

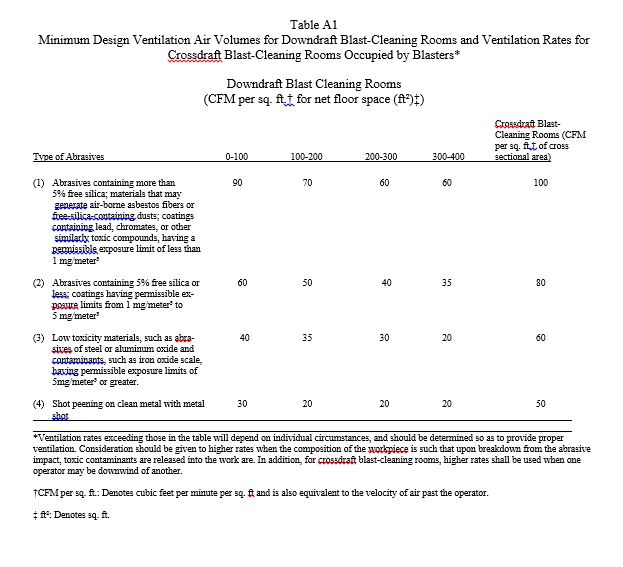

The various room air speeds are determined by the abrasive that will be used in the blast room and the method the room is to be ventilated. The chart below is provided by ANSI and outlined in ANSI Z9.4-1985 – “Abrasive Blasting Operations – Ventilation and Safe Practices”.

Blast Room Ventilation Table

Ventilation System

The most common and economical method of ventilation is “cross-draft”. Basically the calculation for the dust collector size is determined by the following formula:

Width of room x Height of Room x Cross Sectional Air-Speed (FPM) = C.F.M.

Note: The cross sectional air speed is typically 50 f.p.m. for steel grit abrasive and 60 f.p.m. for non-ferrous mineral abrasives.

For example, the dust collector sizing for a room 16’W x 16’H x 60’L that is using steel grit abrasive is calculated as follows:

16’ x 16’x 50 f.p.m. = 12,800 c.f.m. required for a room air-flow rate of 50 F.P.M.

The reclaim system adds an additional air volume to the dust collector that will range between 500-1200 c.f.m.; therefore, the resultant dust collector will be sized for (12,800 c.f.m. + 500 c.f.m.) – a total of 13,300 c.f.m.

There is obviously a lot that goes into building an Abrasive Blast Room. From room size, to proper ventilation. Let ABS Blast’s extensive experience in Blast Room Design help you determine the best design specs to suit your specific needs. Contact Us today for a free quote and see why ABS Blast is an industry leader in Abrasive Blast Room Technologies.