Abrasive Media Reclaim Systems

The abrasive blast media reclaim system is comprised of a floor reclaim and an abrasive separator. The media reclaim floor design can vary from simple “sweep-in” designs to “full” floor reclaims which recover all the abrasive through a grated floor.

Abrasive media reclaim designs vary based on the manufacturer and type of abrasive that is being reclaimed.

When a very light abrasive such as small glass beads or a fine aluminum oxide (i.e.-120 mesh or smaller) is being used, the most common method of media reclaim is a vacuum floor and cyclone separator. This method is also used in most hand cabinets that use suction or pressure blasting.

The most reliable and cost effective method of reclaiming is the mechanical screw floor with a belt and bucket elevator, rotary scalping drum, and air-wash separator.

Reclaim Floor

Types of Reclaim Floors

There are four (4) different designs for an abrasive media reclaim floor. They are single screw, “H”-shaped, “U”-shaped and full reclaim. The selection of the proper design is based on production needs as well as economic concerns.

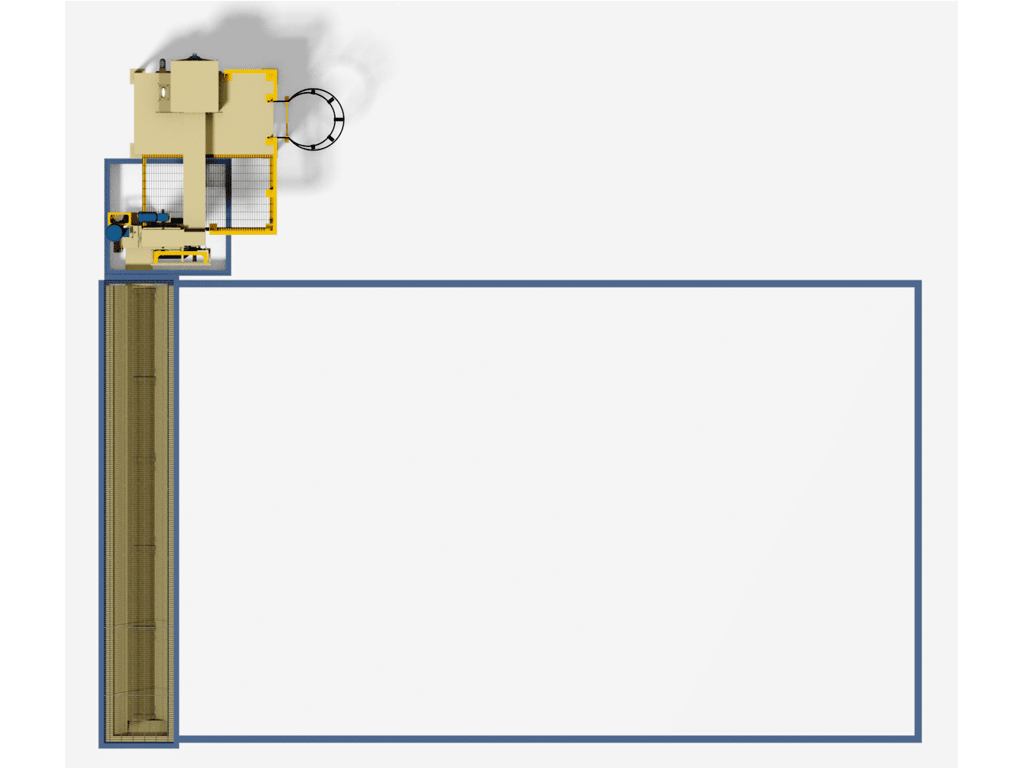

Single Screw Partial Reclaim Floor

A single screw partial reclaim system is the most economical floor design available. The system contains the major components found in abrasive media reclaim systems including metering shed plates, heavy-duty screw, belt and bucket elevator, air wash separator, perforated plate rotary scalping drum separator and abrasive storage hopper with a caged man ladder and handrail.

This reclaim package can be expanded to an “H”, “U”, or full floor reclaim design.

This floor design is for low to medium production levels.

Product Page

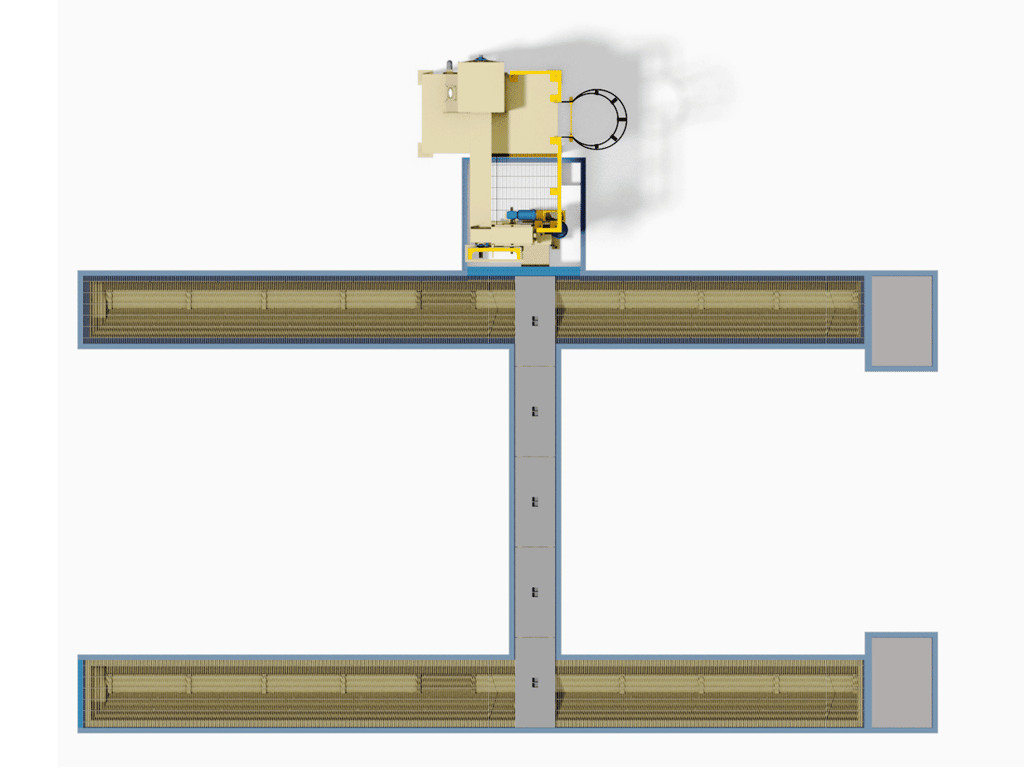

“H”-Shaped Partial Reclaim System

The “H”-shaped partial reclaim system adds two longitudinal metered screw assemblies along each side wall of the blast room. The position of the screw assemblies allows the abrasive delivered from the blasting nozzle, which is either blown or rebounded off the work piece, to strike the side walls and fall into the screws, reclaiming approximately 60-90 percent of the abrasive blast media. The remaining abrasive on the floor is pushed into the screw assemblies at the end of the work shift. The screws are protected from an overload by metering shed plates.

The “H”-shaped floor design is typically utilized in a “flow thru” room configuration where heavy work pieces or material handling devices can drive into the room and position the work piece on the steel covered concrete floor located between the screws.

This floor design is best suited for medium to high production.

Product Page

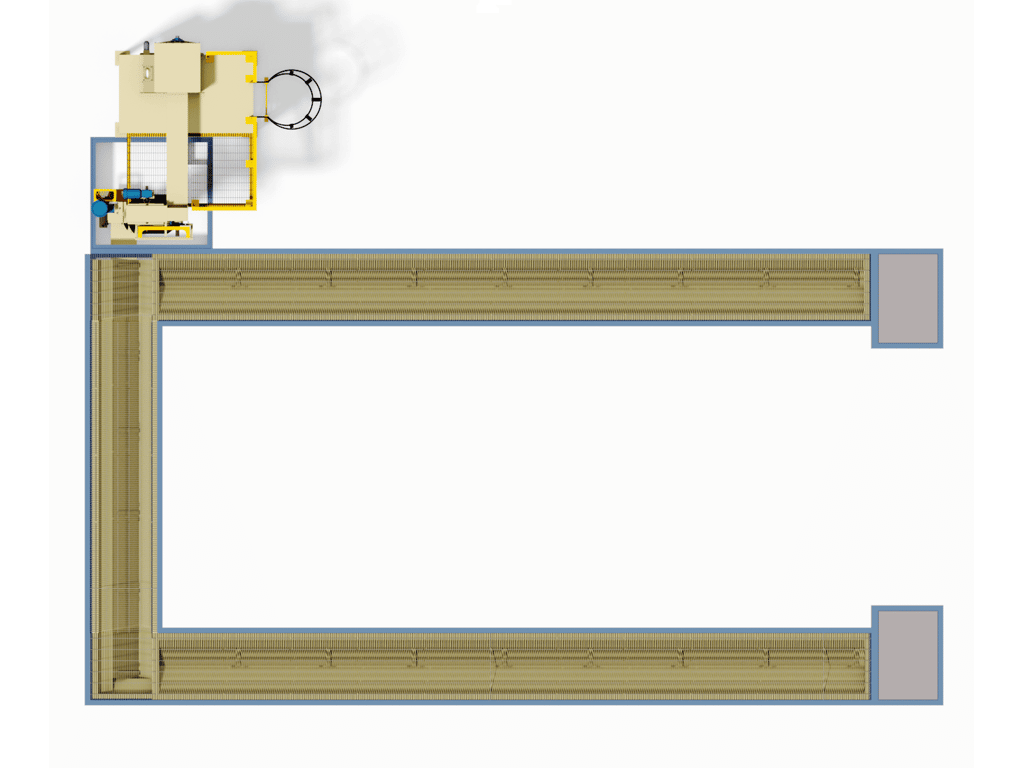

“U”-Shaped Partial Reclaim System

The “U”-shaped partial reclaim system adds two longitudinal metered screw assemblies along each side wall of the blast room and positions the cross screw along the back wall of the blast room. The position of the screw assemblies allows the abrasive delivered from the blasting nozzle, which is either blown or rebounded off the work piece, to strike the side walls and back wall of the abrasive blast room and fall into the media reclaim system.

A “U”-shaped floor design will reclaim 60 to 90 percent of the blast media. The remaining abrasive on the floor is pushed into the screw assemblies. The screws are protected from an overload by metering shed plates. The “U”-shaped reclaim floor design is typically utilized in an “in-out” room configuration where heavy work pieces or material handling devices can drive into the room and position the work piece on the steel covered concrete floor.

This floor design is best suited for medium to high production.

Product Page

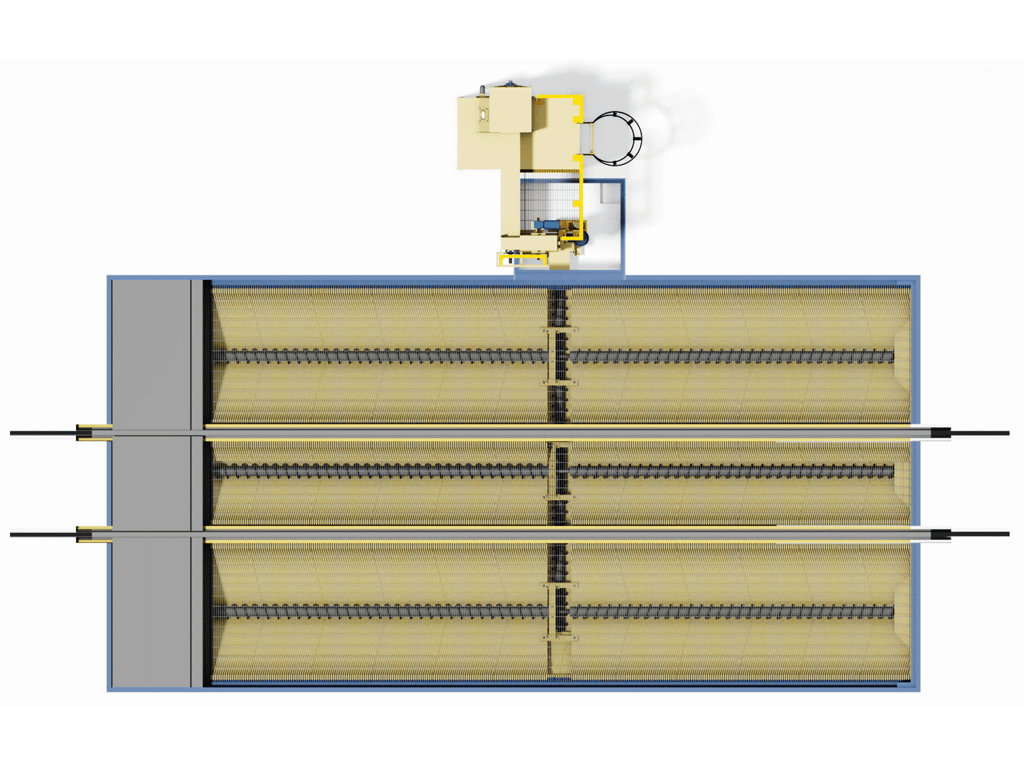

Full Floor Reclaim System

The full floor reclaim system utilizes multiple screw assemblies to create a fully automatic abrasive media reclaim floor system. All the abrasive that is blasted is returned to the separator system. The full floor reclaim design requires that the material handling of the work piece be intricately designed into the configuration of the room. Material handling of the work piece includes a work car/track system, an overhead monorail crane, an overhead bridge crane, or heavy-duty floor grating and support steel sized to allow a forklift to drive onto the media reclaim floor.

The full floor reclaim design can be used with any room configuration. The partial floor reclaim systems will have an added “clean-up” cost associated with the Return on Investment that must be calculated into the justification for Capital Expenditure.

Choosing the right floor configuration to best meet production and cost requirements will result in the quickest return on your investment.

This system is best suited for high production requirements.

Product Page

Full Floor Reclaim System

Material Handling

The material handling method of moving the work piece through your facility or just through the abrasive blast room must be considered so the room is designed for that specific handling device.

As mentioned above, the partial reclaim floor designs lend themselves to forklift trucks or driving the work piece directly into the abrasive blast room, such as construction equipment or trailers.

The full reclaim floor design can be configured for a work car track system, overhead monorail or bridge crane system, or a combination of both.

The abrasive blast room configuration will vary based on your plant layout and the material handling method for the work piece..

Product Page

A “flow-thru” room configuration is designed for work to enter one end of the room and exit the room on the opposite end. This configuration is typically used for an “in-line” production flow of the work pieces. A “flow-thru” design requires more floor space in your facility, in that you typically allow for an in-bound and out-bound staging area prior to the next production phase, such as paint.

An “in-out” room configuration is designed for work to both enter and exit the same end of the abrasive blast room. This configuration is typically used because of space or production flow considerations.

The abrasive blast room and paint booth are usually side-by-side.

This configuration allows for both rooms to be presented the work piece from a variety of sources and directions, while minimizing factory floor space requirements.

Production Levels

The amount of abrasive blasting that is done in an 8-hour period and the number of blasters required for that production level is another factor that dictates a blast room design. For example, if you are currently operating with four (4) blasters in an outdoor sandblasting operation, you will require an abrasive blast room with enough room, abrasive capacity and reclaim equipment to accommodate this production level.

The abrasive media reclaim systems and room designs will vary in size and capacity based on production levels.

The chart on the following page is a guideline that can be used to size the blast room based on your production requirements:

| NOZZLE ORIFICE SIZE | ||||||

| 1/2″ | 7/16″ | 3/8″ | 5/16″ | 1/4″ | 3/16″ | |

| Air CFM at 100 PSI | 338 | 254 | 198 | 137 | 81 | 45 |

| Shot Blast Hose I.D. | 1 1/2 | 1 1/4 | 1 1/4 | 1 1/4 | 1 | 3/4 |

| Air Inlet I.D. | 2 | 1 1/2 | 1 1/2 | 1 1/4 | 1 1/4 | 1 |

| Steel Abrasive Lb/Hr | 6325 | 4950 | 3666 | 2600 | 1710 | 910 |

| SURFACE COND. | SQUARE FEET PER HR. | |||||

| White Metal | 1/2″ | 7/16″ | 3/8″ | 5/16″ | 1/4″ | 3/16″ |

| Loose Mill Scale | 245 | 190 | 138 | 93 | 58 | 30 |

| Tight Mill Scale | 200 | 161 | 113 | 79 | 47 | 25 |

| Heavy Rust | 120 | 90 | 66 | 47 | 28 | 15 |

| Multicoats | 95 | 72 | 52 | 37 | 23 | 12 |

| Near While | 1/2″ | 7/16″ | 3/8″ | 5/16″ | 1/4″ | 3/16″ |

| Loose Mill Scale | 260 | 197 | 149 | 100 | 59 | 33 |

| Tight Mill Scale | 213 | 168 | 116 | 82 | 60 | 26 |

| Heavy Rust | 128 | 100 | 70 | 59 | 30 | 16 |

| Multicoats | 100 | 80 | 56 | 40 | 24 | 13 |

| Commercial | 1/2″ | 7/16″ | 3/8″ | 5/16″ | 1/4″ | 3/16″ |

| Loose Mill Scale | 625 | 490 | 351 | 246 | 150 | 80 |

| Tight Mill Scale | 419 | 322 | 233 | 160 | 100 | 50 |

| Heavy Rust | 311 | 242 | 172 | 119 | 70 | 38 |

| Multicoats | 206 | 159 | 113 | 78 | 47 | 25 |

| Brush | 1/2″ | 7/16″ | 3/8″ | 5/16″ | 1/4″ | 3/16″ |

| Loose Mill Scale | 1261 | 983 | 717 | 495 | 300 | 158 |

| Tight Mill Scale | 1261 | 983 | 717 | 495 | 300 | 158 |

| Heavy Rust | 1261 | 983 | 717 | 495 | 300 | 158 |

| Multicoats | 1261 | 983 | 717 | 495 | 300 | 158 |

Conclusion

A properly designed abrasive blast system will provide your company the tools it needs to meet the demands for a clean environment as well as providing a good Return-On-Investment.

Recycling blast abrasives saves money by reducing waste. The enclosed blast room saves money by allowing production to continue regardless of outdoor weather conditions.

ABS Blast offers a full spectrum of abrasive media reclaim system designs and room configurations. From economical single screw partial reclaim floors to highly efficient full floor reclaims, ABS Blast will help you design a solution uniquely tailored to your production and economic needs.