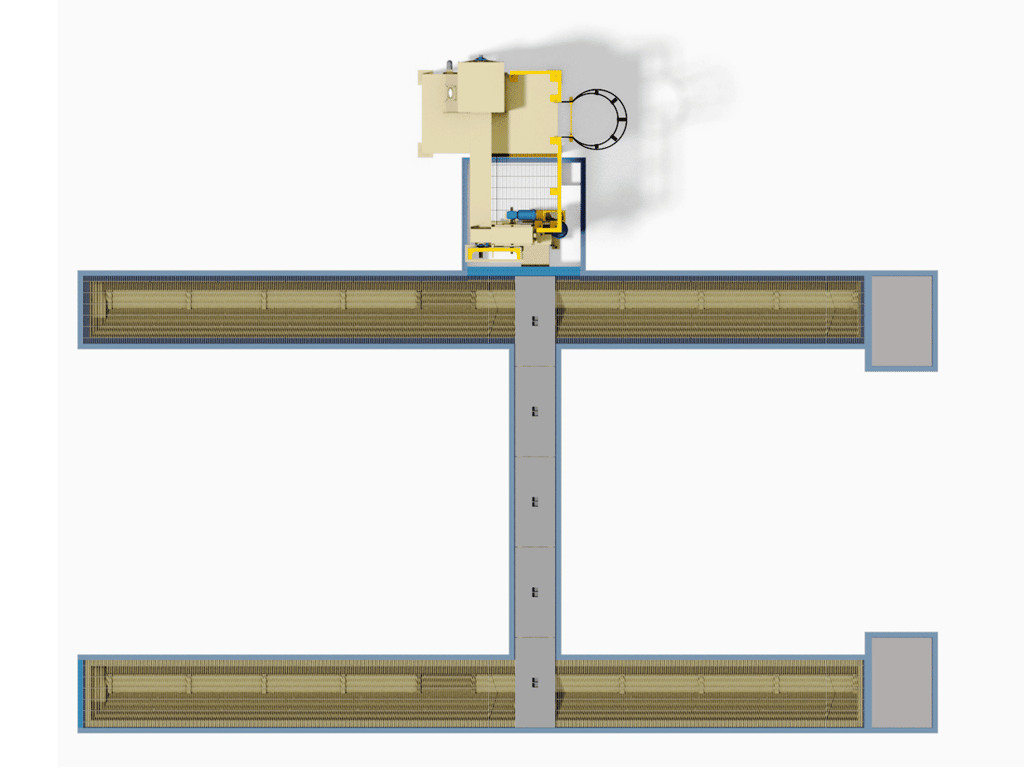

H-Shaped Partial Reclaim System

The “H”-shaped partial reclaim system is typically used in an enclosed abrasive blast room design that allows for positioning of the work piece in between two longitudinal metered screw assemblies along each side wall of the blast room. The “H”-shaped floor design is typically utilized in a “flow-thru” room configuration where heavy work pieces, and/or material handling devices, can drive into the room and position the work piece on the steel covered concrete floor located between the longitudinal screws. This system is best suited for medium to high production.

How It Works

The position of the screw assemblies allows the abrasive delivered from the blasting nozzle, which is either blown or rebounded off the work piece, to strike the side walls and fall into the screws; automatically reclaiming approximately 60-90 percent of the blast media. The remaining abrasive on the floor is pushed into the metered shed plate screw assemblies at the end of the work shift.

Contact Us Today